data is helpful when assessing the overall health of the crop, di-

agnosing problems and ascertaining what factors may have posi-

tively or negatively affected their crop.

A grower must also ensure that the plants are getting fed prop-

erly and on time. Depending on the stage of growth of the crop

and the amount of light available, a grower alters the

concentra-

tion of the feed solution.

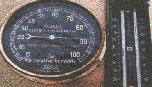

Hygrometer and thermometer for monitoring temperature

and humidity